1923-2014

STEPHANIE KWOLEK

It’s hard to quantify just how many lives have been saved and injuries prevented by high-strength industrial fibres. In 1965, Stephanie Kwolek’s extraordinary hard work paid her back with the serendipitous discovery of a new type of material, whose simultaneous strength, lightness and stiffness gave it boundless possibilities for use in a range of products that would transform industries and improve countless lives. You may well have heard of the most famous of them – Kevlar® – for its use in bulletproof vests, helmets, fighter jets, Formula 1 cars, fireproof suits, tyres and many other products.

Kwolek was born in 1923 in Pittsburgh, Pennsylvania. When she was ten years old, her father passed away but his passion for the natural sciences lived on in his daughter. She studied chemistry at Carnegie Mellon University, graduating aged 23. Originally set out to pursue a career in medicine, she couldn’t resist the lure of organic chemistry, sparked by her time working as a chemist with the DuPont Company, first in Buffalo, New York, then in Wilmington, Delaware. For almost two decades she became absorbed in her work with a type of chemical compound called ‘polyamides’. This involved meticulous experimentation, developing different solvents of these compounds and testing their ability to withstand high heat and pressure.

The amazing thing about her discovery in 1965 – that certain polyamides could line up in the right way to exhibit these strong and flexible characteristics – is that, on the face of it, the particular solution she’d prepared looked a hopeless case. You’d normally expect a suitable solution to look more like transparent gel, not a cloudy liquid. But Kwolek followed her instincts and tested it anyway, and realised it had potential as the basis for a series of world-changing industrial fibres.

As she was working at DuPont at the time, the company greatly benefited from her discovery, assigning teams of scientists to work on the applications of the new material, starting with tyres. Kevlar products only hit the market in 1975, and since then DuPont earned billions thanks to Kwolek and her incredible invention. Since she assigned all her patents to the company she never directly benefited from this discovery. She was nevertheless proud to be saving lives and contributing to society in a meaningful way.

This tenacious energy and her willingness never to accept defeat became one of her trademark qualities – it even saw her land her first job at DuPont when she had been told at interview to wait several weeks and instead demanded an immediate answer as she had an offer from another employer.

After her retirement in 1986, she kept consulting DuPont and received the rare distinction of being awarded, as a woman, the Perkin Medal (in 1997) and the National Medal of Technology (in 1999). She would leave a final legacy in the years before her death in 2014 in mentoring a stream of young female scientists-to-be.

“All sorts of things can happen when you’re open to new ideas and playing around with things.”

Stephanie Kwolek

kevlar

Kevlar is now used in the full spectrum of industries, from personal armor and protective gear, to tyres, sports equipment and even cryogenics. On an equal weight basis, Kevlar is five times stronger than steel. Today Kevlar is used in tyres, firefighters’ and lumberjacks’ suits, bulletproof vests and helmets, cut-resistant gloves, fiber-optic cables, boat hulls, racing sails, sporting equipment, fighter jets and Formula 1 cars.

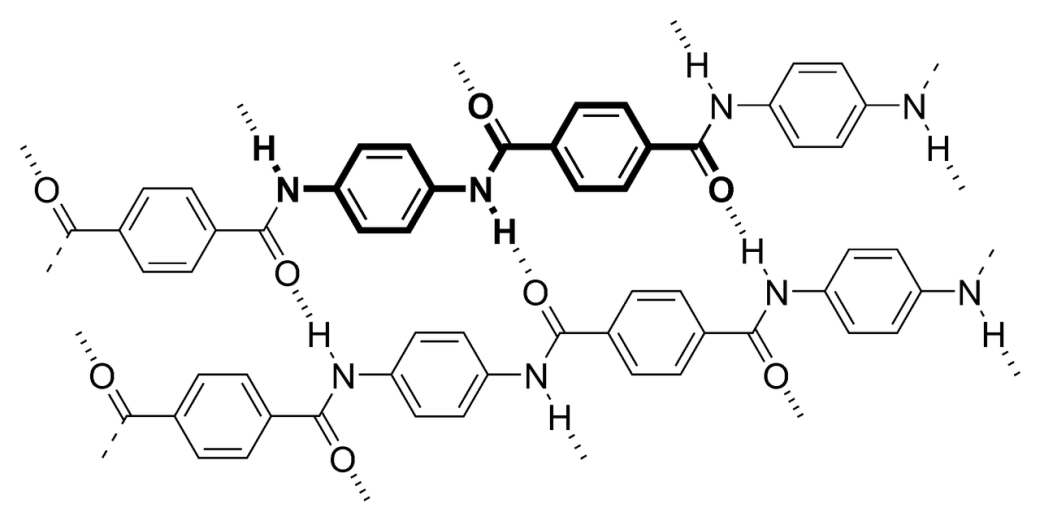

Kevlar is a para-aramid synthetic fibre made through thousands of synthetic plastics created through polymerisation (the joining together of long chain molecules). In Kevlar, the internal structure of its molecules is what makes it so incredibly strong – they are arranged in parallel, regular lines and are tightly knitted together. To find out about Kevlar in far more detail, visit Explainthisstuff.Com.

One of its benefits is its extreme lightness relative to other protective properties, making it a great basis for heat-resistant gloves and clothing, used by firefighters for example. Its tensile strength has seen it used to string Japanese Archery bows – it is cheaper than the hemp-based alternative – whilst also used for stringing tennis rackets and as an addition to table tennis bats, offering more bounce and lightness.

Kevlar is most known for its uses in the military – anywhere from helmets and bulletproof vests to fighter jets and armoured vehicles. Since it is so much stronger than steel and so lightweight it offers superior protection against ballistics and fragmentation. It can even be used to reinforce a building in high threat-zones, to protect it against bomb blasts. Walls that would otherwise collapse are kept together by Kevlar.

Nike used it in their Elite II series of basketball shoes, launched in 2013, to reduce elasticity at the shoe’s tip. Numerous bicycle manufacturers have used it to strengthen their tyres and minimise the risk of punctures.

Kevlar even has an application in music – it’s often used in the skin of snare drums which require extreme tightness (to allow for a sharper, cleaner hit sound) and can be found in everything from woodwind reeds, to bow strings, to bass speakers.

If all that wasn’t enough, you find Kevlar in non-stick frying pans (as a replacement for Teflon), suspension bridge cables, fire dancing wicks, smartphone cases and wind turbines.

Indeed, it’s hard to find an industry into which it hasn’t stretched it’s long (very strong, very flexible) tentacles.

Fighter jets

photo by Jacek Dylags, Unsplash

F1 cars

photo by Krish Modi, Unsplash

Bulletproof vests

photo by Jakob Owens, Unsplash

Heat resistant clothing

photo by Adrien, Unsplash

Car tyres

photo by Goh Rhy Yan, Unsplash

Sail boats and sails

photo by Diego Romeo, Unsplash

Helmets

photo by Israel Palacio, Unsplash

Hiking boots

photo by Sven Brandsma, Unsplash

Bicycle tyres

photo by Moshari, Unsplash